B1420 Crown Core Drill Bit Series with 1/4-7" Drill Connection by...

B1420 Crown Core Drill Bit Series with 1/4-7" Drill Connection by Husqvarna

$85.50

542788309

B1420 Crown Core Drill Bit Series with 5/8-11 Drill Connection by Husq...

B1420 Crown Core Drill Bit Series with 5/8-11 Drill Connection by Husqvarna

$85.50

542788309

542788309

Elite-Drill D10 TW Diamond Cocnrete Core Drill Bits by Husqvarna...

Elite-Drill D10 TW Diamond Cocnrete Core Drill Bits by Husqvarna

$72.53

535694502

535694502

Professional® B1420 WS Diamond Core Bit for Concrete by Husqvarna...

Professional® B1420 WS Diamond Core Bit for Concrete by Husqvarna

$107.73

586669202

586669202

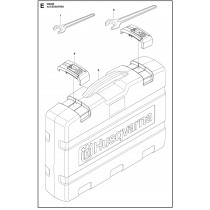

502294503 Carrying Case for DM 230 Drill Motors by Husqvarna...

502294503 Carrying Case for DM 230 Drill Motors by Husqvarna

$94.10

501072204

501072204

502634903 Label for DM 230 Drill Motors by Husqvarna...

502634903 Label for DM 230 Drill Motors by Husqvarna

$0.00

501072204

501072204

502634904 Label for DM 230 Drill Motors by Husqvarna...

502634904 Label for DM 230 Drill Motors by Husqvarna

$0.00

501072204

501072204

502634905 Label for DM 230 Drill Motors by Husqvarna...

502634905 Label for DM 230 Drill Motors by Husqvarna

$0.00

501072204

501072204

502635302 Label for DM 230 Drill Motors by Husqvarna...

502635302 Label for DM 230 Drill Motors by Husqvarna

$0.00

501072204

501072204

503263030 O-Ring for DM 230 Drill Motors by Husqvarna...

503263030 O-Ring for DM 230 Drill Motors by Husqvarna

$0.00

501072204

501072204

504571302 Cable Assy for DM 230 Drill Motors by Husqvarna...

504571302 Cable Assy for DM 230 Drill Motors by Husqvarna

$0.00

501072204

501072204

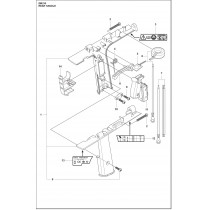

505441104 Handle Assy for DM 230 Drill Motors by Husqvarna...

505441104 Handle Assy for DM 230 Drill Motors by Husqvarna

$246.00

501072204

501072204

505576303 Motor Housing for DM 230 Drill Motors by Husqvarna...

505576303 Motor Housing for DM 230 Drill Motors by Husqvarna

$73.30

501072204

501072204

505576504 Rotor for DM 230 Drill Motors by Husqvarna...

505576504 Rotor for DM 230 Drill Motors by Husqvarna

$309.00

501072204

501072204

521907201 Cable for DM 230 Drill Motors by Husqvarna...

521907201 Cable for DM 230 Drill Motors by Husqvarna

$0.00

501072204

501072204

-210x210.jpg)

-210x210.jpg)

-210x210.jpg)

-210x210.jpg)